WooLee Winders are our #1 technical support issue; and it's mostly due to a failure to clean and maintain your WooLee Winder properly.

It's not possible to properly service your WW unless you disassemble it, and most folks are terrified to do it, so we frequently get a phone call that goes like this:

miniSpinner Owner: “I love my miniSpinner, but… it keeps stopping.”

HansenCrafts: “I’m guessing you have a WooLee Winder. When did you last clean it?” (This is a trick question,‘cause we already know what’s coming.)

miniSpinner Owner: (Long pause, embarrassed giggle.) “Oh! I’ve never cleaned it”

I can’t tell you how many times we’ve had this conversation. WooLee Winders, like any other mechanical thingy, need to be cleaned and serviced periodically to keep them working well.

miniSpinner stops unexpectedly or 3 lights flash

If your WW is really dirty, it will require considerable brake tension to overcome the friction from dirt, fuzz, congealed oil, and so on. Eventually the brake tension will reach the point that it trips your miniSpinner’s motor-overload protection, or it simply won't wind on at all because the mechanism is jammed with dirt and fiber.

That’s when we get The Phone Call.

When should I clean my WooLee Winder?

Clean your WW regularly. Dust and fiber collects in the drive screw and the lubrication that you used will get sticky over time and needs to be cleaned out and replaced.

You definitely don’t want it to look like this! Yuck! Note the fuzz wrapped around the travel screw at the left end near the small gear, and beside the traveler toward the other end.

I wonder why it doesn’t work very well?

Also: If you just cleaned it and it suddenly quits working properly, it's likely some junk found its way into the (recently cleaned) mechanism. So, if it's not working well, take it apart and clean it again!

Also: If you just cleaned it and it suddenly quits working properly, it's likely some junk found its way into the (recently cleaned) mechanism. So, if it's not working well, take it apart and clean it again!

Brake tension

--- In general, use ONLY the minimum brake tension needed to wind on your thread. ---

A poorly functioning WW requires excessive brake tension to overcome the friction in the WW mechanism; it's the most common symptom associated with WWs.

The brake band spring should be stretched very little, or not at all, when the flyer is turning clockwise and winding on properly. If it's stretched more than 1/16" or so, it means there's too much friction in the WW somewhere (or you’re using more brake tension than necessary).

Erratic takeup

Erratic takeup is usually caused by sticky/dirty areas on the travel screw or a buildup of fuzz at one end of the travel screw inside the flyer arm where you can’t see it.

To compensate for the lack of takeup at the sticky spots, you must increase the brake tension to overcome the friction. When your WW gets past the sticky spot, it will pull like crazy because of the excessive brake tension.

Cleaning and Lubrication

Follow the excellent cleaning instructions supplied with your WooLee Winder.

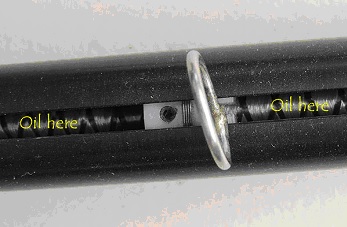

We use Super Lube Oil with PTFE to lubricate the WooLee Winder travel screw. Apply an occasional drop of Super Lube* oil (not grease!) directly to the travel screw as shown below:

Also apply a film of Super Lube Grease to the outside of the orifice tube (see pic at the end of this article) where it goes into the miniSpinner’s ball bearing.

If your bobbin rattles, put a blob of Super Lube Grease on the flyer shaft before you install the bobbin.

Problems after cleaning?

When you cleaned your WW, did you disassemble it and wash the parts in hot soapy water? You can't clean it properly unless you do! Most folks are terrified to do this, but it's quite simple if you follow the instructions.

If it’s not working right after cleaning, these are the most common errors:

- Check that the leg of the traveling eye is fully inserted into the plastic traveler. If not, the upright will hit the end of the slot and jam before reaching the end of its travel.

- Check that the tiny Teflon tube is in place on the upright leg of the traveling eye.

- Don’t overtighten the small Allen setscrew that holds the “foot” of the traveling eye, it can deform the traveler and cause it to bind on the travel screw.

- Check that the bushing at the near end of the travel screw is inserted pointy end first.

- Check that the stationary eyelet's screw lines up with the hole in the above bushing. It should go all the way into the threaded hole with very little resistance. If it won't go in all the way, the hole probably isn't lined up and the screw is pressing on the outside of the bushing.

- Check that the large white gear turns freely and isn’t binding on its shaft.

Testing your WW for function:

Check that the large white gear turns freely and use a _VERY_ gentle touch with your finger to turn that gear _SLOWLY_ while you feel for drag throughout the entire range of travel of the moving eye. If it doesn't turn freely, determine what’s causing it to stick and correct the problem.

Bobbin endplay

There needs to be a little bobbin endplay, about 1/16". If there's no endplay you'll need more brake tension to overcome it and that's not desirable. If there's really excessive endplay the gears may not engage, so the mechanism won't work properly. It's easy to see this.

Third party bobbin problems

If you're using third-party 3D printed bobbins, they can be draggy for a variety of reasons.

We’re not a fan of 3D printed bobbins, which is why we don’t make them; we machine HansenCrafts bobbins of solid and far more durable material than 3D printed bobbins.

WW Wooden Bobbin problems

If you're using older, original WW wooden bobbins, check to see that they slide easily onto the shaft and turn freely. Sometimes the hole in the white gear shrinks and binds on the flyer shaft, which will require more brake tension to overcome. The hole needs to be reamed back to the intended diameter (0.255 inches).

If the brake tension is erratic or grabby, sand the bottom of the bobbin brake groove to remove any excess finish or to smooth any rough edges.

HansenCrafts WW-compatible bobbins

If you're using the excellent WW-compatible bobbins that we make, you should be fine; we've never encountered a problem with them. If the brake tension seems a little aggressive, just draw a line in the bottom of the brake groove with a soft lead pencil; the graphite in the pencil lead will lubricate the brake band and smooth the brake action.

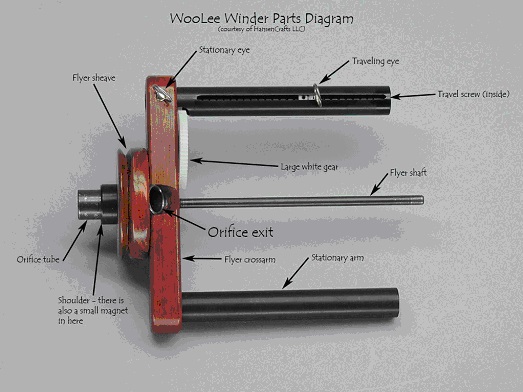

WW Parts Diagram:

*Super Lube products are available from HansenCrafts. WW cleaning instructions came with your WW, or we will send you a new copy.